CHLOR ALKALI PLANTS

We help to industrialize regions through the local production of chlorine and other products from chlor alkali plants for water treatment and purification

WELYSIS

Chlor-Alkali Plant

As operators of electrolysis plants, we have the know-how in both construction and operation. Our modular plants are highly efficient and are delivered and installed all over the world.

All our electrolysis plants are automatically part of WIN (Welysis International Network), where through our 5 pillars we share best practices, training, knowledge, quality and experience.

Leaders in technological and operational innovation

Rapid return on investment

Economic and social benefits

SCALABLE AND MODULAR CHLOR ALKALI PLANTS

We design, build and install three standard plant types for different production capacities. Thanks to their modular design, production can be scaled up in line with growth forecasts.

News

FAQs about Chlor Alkali Plants

At Welysis, we specialize in cutting-edge solutions for chlor alkali plants, helping industries optimize production, enhance efficiency, and ensure sustainability. Our expertise covers advanced electrolysis technologies, process optimization, and compliance with environmental standards.

In this section, you’ll find answers to the most common questions about chlor alkali plants, their processes, applications, and industry best practices. Whether you are looking for insights on energy efficiency, safety, or regulatory compliance, our FAQs provide valuable information to help you stay informed.

Explore the topics below to learn more about chlor alkali plants and how Welysis can support your operations.

A chlor alkali plant primarily produces three essential chemicals:

Our electrolysis plants are versatile and can produce a variety of essential chemicals, which are crucial for various industrial applications:

- Sodium Hypochlorite (14-17%): widely used as a disinfectant and bleaching agent.

- Caustic Soda (32-50%): A fundamental chemical compound in the manufacture of paper, textiles, detergents and many other industrial products.

- Hydrochloric Acid (33%): Important in the production of vinyl chloride for plastics, and in metal processing.

- Hydrogen: A versatile gas that can be used as a fuel, in the production of ammonia and in other chemical processes.

Energy consumption depends on the electrolysis technology used. A membrane cell chlor alkali plant requires 2,500 to 3,000 kWh per metric ton of chlorine produced. Optimizing energy sources, including renewables, can reduce operational costs.

The space requirement depends on plant capacity, technology, and infrastructure needs. A modular chlor alkali plant can be designed to fit within a compact footprint, typically ranging from 500 to 5,000 square meters, allowing for flexibility in industrial settings.

A modular chlor alkali plant can be installed and commissioned within 6 to 12 months, depending on site conditions, permitting, and equipment availability. Pre-assembled modular units significantly reduce setup time.

To ensure safety, chlor alkali plants implement:

- Automated leak detection and emergency shutdown systems.

- Personal protective equipment (PPE) for workers handling chlorine and caustic soda.

- Proper ventilation and scrubbing systems to manage gas emissions.

Yes. Modular chlor alkali plants allow for scalable expansion by adding additional electrolysis cells and support systems. Welysis provides customized capacity upgrades based on market demand.

Key strategies include:

- Using energy-efficient membrane technology to lower electricity costs.

- Implementing process automation to reduce labor and downtime.

- Utilizing byproducts (hydrogen) for additional revenue streams.

Chlor alkali plants must comply with local and international environmental regulations, including:

- Air emission permits for chlorine and hydrogen.

- Water discharge permits for brine treatment.

- Hazardous chemical storage and handling approvals.

Membrane cell technology is the preferred method for modern chlor alkali plants because it:

- Eliminates mercury and asbestos, making it environmentally safer.

- Reduces energy consumption, improving efficiency.

- Produces high-purity sodium hydroxide.

Welysis provides comprehensive support, including:

- 24/7 technical assistance and troubleshooting.

- Spare parts supply and equipment upgrades.

- Ongoing process optimization consulting.

Local chlor alkali plants reduce supply chain risks, transportation costs, and import dependencies, ensuring a stable and cost-effective chemical supply.

Quality is maintained through:

- Regular brine purification to remove impurities.

- Strict monitoring of electrolysis conditions.

- Adhering to international chemical quality standards

To increase profitability, consider:

- Optimizing energy efficiency through advanced membrane cells.

- Diversifying product applications to expand market reach.

- Reducing waste and maximizing byproduct utilization.

MORE INFORMATION? CONTACT US

Contact us to explore possibilities for collaboration.

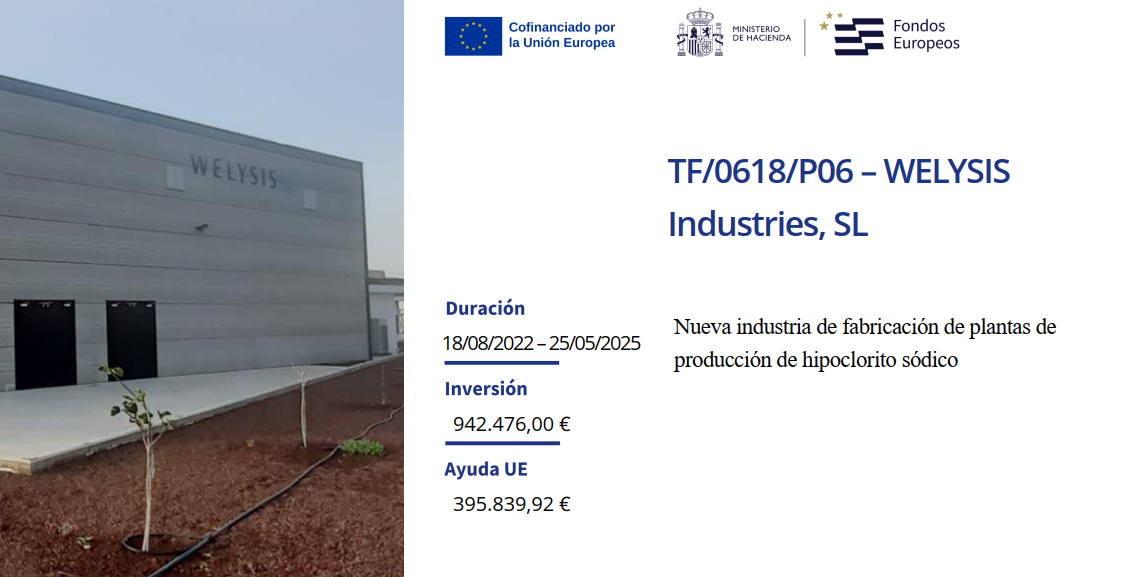

Modernisation and diversification of the industrial sector 2022: “Electrolysis plant factory”

Project co-financed by the European Social Fund – Impulse FP DUAL