In the context of the transition to renewable energy, it is crucial, to adopt strategies that optimise the use of electricity. In this article we explore how load shifting in chlor-alkali plants can generate energy cost savings and reduce CO2 emissions.

While chlor-alkali electrolysis plants are essential in meeting the demand for chemicals such as chlorine and sodium hydroxide, which are essential for many industries, they are also highly energy intensive. This high energy consumption makes them more vulnerable to rising electricity costs.

Energy challenges and reduction in co2 emissions in electrolysis process

The electrolysis process consumes large amounts of electricity, and accounts for a significant part of operating costs. In Germany, for example, these plants are responsible for more than 2% of total electricity consumption, making them key players in the energy grid. Also, the increasing share of renewable energy sources has intensified the fluctuation of electricity prices, which in turn affects the operating costs of the plants.

During periods of high renewable energy production, electricity prices decrease significantly, which provides an opportunity for plants to adjust their operations, reducing costs when prices are low.

Demand response: an opportunity for savings

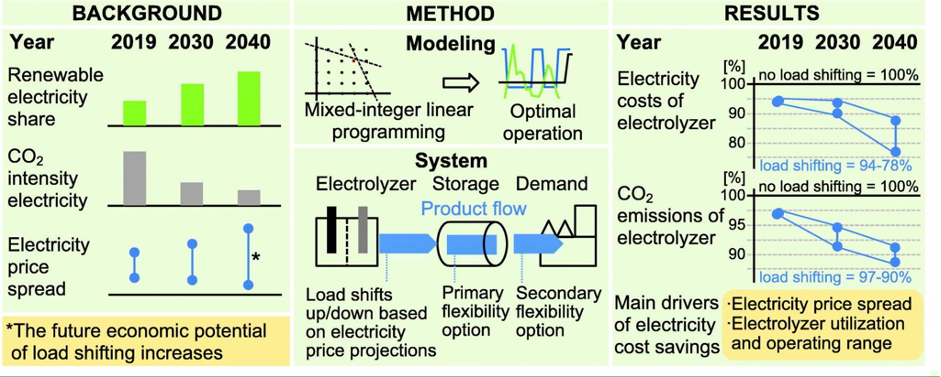

Demand response allows electrolysis plants to adjust their energy consumption according to market conditions. Shifting production to lower-priced time slots not only reduces operating costs, but also helps to stabilise the electricity grid. According to one study, implementing demand response strategies can generate electricity cost savings of between 5.8% and 22%, depending on the plant’s operational scenario and flexibility.

As well as the economic benefits, demand response can generate a reduction in CO2 emissions, ranging from 2.7% to 10.1%. This is made possible, thanks to the consumption of energy mainly from renewable sources during periods of low demand, which also allows plants to reduce their carbon footprint in an efficient way.

Image source: https://www.sciencedirect.com/science/article/abs/pii/S0306261923016276

Future projections: 2030 and 2040

The study’s projections for 2030 and 2040 forecast an increase in the variability of electricity prices due to the increased use of renewable energy sources. In 2019, the difference between the highest and lowest prices was 28%, but by 2040 this difference is expected to reach 87%. This increases opportunities to implement load shifting strategies, with savings of up to 22% in electricity and reductions of 10% in CO2 emissions.

Factors driving savings

There are several factors that influence the potential for electricity cost savings and reductions in CO2 emissions in electrolysis plants. Variability in electricity prices and the operational range of electrolysis plants are among them. The greater the margin between high and low prices, the greater the incentive for plants to adjust their production to the demand window and take advantage of the lowest cost times. Moreover, the greater the operational flexibility of electrolysis plants, the greater their ability to adjust to efficient consumption.

As the proportion of renewable energy from sources such as solar and wind increases, so does the opportunity to consume clean electricity and reduce CO2 emissions.

Discover how Welysis electrolysis plant can reduce costs and emissions

Contact our experts today!Challenges and opportunities in CO2 emissions reduction and saving costs

While demand response offers benefits, it also presents its own challenges. Plants must have advanced control systems to manage consumption in real time. This is one of the strengths of our Welysis plants, which incorporate advanced sensorisation, enabling real-time decision making for any given need.

Furthermore, evolution of the electricity market and its energy policies will influence the viability of these strategies.

Load shifting in chlor-alkali plants is a very significant opportunity to reduce costs and emissions in the context of energy transition. Plants that adopt flexibility strategies will be better positioned to benefit from fluctuating prices while also contributing to decarbonisation goals.

Sources:

- https://www.sciencedirect.com/science/article/abs/pii/S0306261919315673

- https://www.sciencedirect.com/science/article/pii/S187770581731192X

Conclusion

The potential for electricity cost savings and CO₂ emissions reductions in electrolysis plants is strongly tied to the adoption of flexible energy management strategies. By optimizing electricity consumption based on market fluctuations and integrating renewable energy sources, these facilities can significantly lower operational expenses while reducing their carbon footprint.

Studies indicate that leveraging demand-side response mechanisms and adjusting production schedules to off-peak hours can yield substantial economic and environmental benefits. Additionally, as grid decarbonization progresses and electricity price volatility increases, the incentives for implementing these strategies will become even more compelling.

Future advancements in energy storage and smart grid technologies will further enhance the feasibility of cost-effective, low-emission electrolysis. Therefore, companies in this sector must proactively adapt to these emerging trends to remain competitive and contribute to global sustainability goals.

Contact us for more information about how to save costings and reduce CO2 emissions with Welysis.